Free Radical Oxidation BioWater Technology Responsive Mechanisms

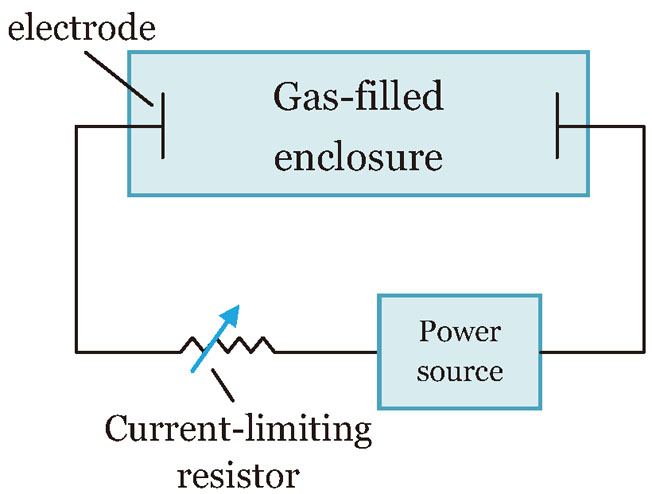

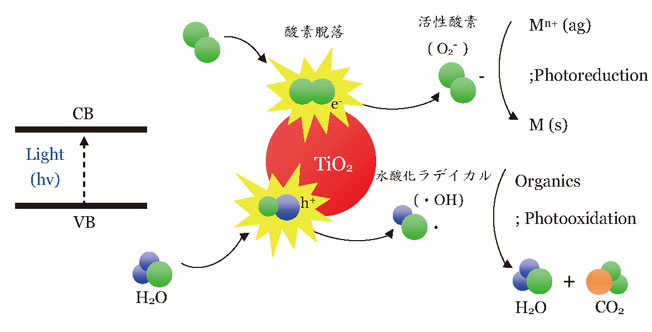

Super Fradox Free Radical Oxidation BioWater Technology responsive mechanisms activate through accelerating the electrons in the electron donor, such that the electron and gas molecules such as oxygen and hydrogen react to produce oxygen atoms, ozone, and hydrogen atoms. The reaction of these particles is very strong, and after contacting water there occurs a series of chemical reactions, and the activity of Bioceramic catalytic converter core conversion works to produce a greater amount of free radicals, OH * radicals, and the free radicals undergo collision with an organic molecule that reacts, and generate stable hydrocarbon molecules, carbon and oxygen molecules or water molecules.

Advantages of Free Radical Oxidation BioWater Technology Water Purification Method

1. The treatment process is simple, with easy to control operating conditions, providing strong oxidation ability, and fast reactivity.

2. There is no need to add any chemicals, and it will not cause environmental pollution; final reaction products are carbon dioxide and water, and it does not pollute

the cleaning materials, nor generate any secondary pollution.

3. The organic pollutants collected in bag filters and in the loop process, these can also be broken down and cleared, producing a very small amount of sludge.

4. Maintains a highly productive operational time for cleaning tank.

5. Fully compatible with existing ultrasonic wet cleaning method processes.

6. Reduces manpower requirements for maintenance and losses from downtime.

7. Reduces electricity required for energy savings, helping protect the environment.

Free Radical Oxidation BioWater Technology Water Purification Related Applications

(I) Germicidal Disinfectant

1. For aquaculture, and home use water germicidal control.

2. Cold-water water quality algal inhibition and Legionnaires’ Disease bactericidal inhibition.

3. Swimming pool, spa, warm water pool germicidal disinfectant.

4. Water reservoir algal inhibition control and disinfectant.

(II) Pollutant Handling

1. Landscaping water loop, underground water reclamation purification and handling.

2. Industrial wastewater decomposition of pollutants, such as COD, BOD oxidation decomposition, oxidation and decomposition of organic chlorophenols, dye decolorization and Cyanide (CN-), sulfide S2-pollution treatment

3. Aquaculture operations reduction of NH3, NO2, and organic pollutant purification and reclamation.

Case study of Food processing factory conveyor belt, vessel grease cleansing and disinfection