A. Working principle of the device

At present, water quality improvement still uses de-ironization by aeration, chemical coagulation, gravitational filtration and particle filtration. Considering water activation, there are many ways such as energized low potential ceramic activation, magnetic separation, electromagnetic induction, high-frequency vibration, catalyst activation and so on. The basic aim of improvement is increasing water potential, in order to restore the activity of water molecules, and thus solve the problem of limescale.

The surface of colloidal molecules in water carries an electric charge consisting of fixed layer and diffuse layer, two layers to achieve a balance between electric charges causing the colloid to be stable. In order to break colloid stability, Chem-free device is designed with high electric potential and shear, to reduce the thickness of the fixed and diffuse layers and form a compression of electric double layer, reducing the surface potential energy, reducing electrostatic repulsion between colloidal particles, increasing opportunities for contact between colloidal particles, supplemented by fluidized bed or spoiler design, enlarging crystal type and surface area of the colloidal

particles group, so particles float and remain suspended,with hydrated silica as the core,constantly absorbing calcium ions,magnesium ions or iron oxide(Fe2O3). The formation of non-crystalline large particles group precipitates in water and will be discharged during blowdown. Most of the calcium or magnesium ions in water become non-crystalline soft sludge due to adsorption with silica, not with the negatively charged ions such as carbonate (CO3-2) or sulfate(SO4-2) and unable to form into calcite crystals found on machines or surface of pipe, which is commonly known as scale.

As the function between silica and charged ions needed a force to form,the charged particles (with charge q) passing through the magnetic field (B) require a certain speed (V), to form the required force (F = q × V × B). In other words, water must be in a flowing state. Stagnant water is unable to produce the results.

Water treated by our device can be maintained at high conductivity. That is, allowing a higher concentration of dissolved ions floating in suspension, without the formation of scale deposits on the surface of equipment or piping. Using in industrial steam boilers, it can reduce blowdown and also save the amount of energy burned.

This device has low-density inert metal foam on special high-temperature sintered and energized ceramic powder and water molecule shock fluid turbulence activation, resulting in enhancing the potential of water molecules to dissolved the old scale on one hand, and on the other hand, to change the electric double layer collision probability on pipe walls, causing scale crystalline patterns change to achieve anti-scale purpose.

This equipment is designed to use the kinetic energy of water flow velocity, to start the intermittent water potential interference produced by the tourmaline within the device, to promote ion interference components to sustain intermittent micro positive electric discharge, so that the water within the device will be affected by the discharge and kill biological colloidal substances, prevent growth habitat, prevent production of new biological colloidal substances, and make the old bio-colloidal material fall off, to keep the whole processed water body clean, sterile and odorless. The intermittent nature of the special micro-voltage discharge technology will not cause the pipeline to form weak current to create corrosion so, please feel at ease to use.

The catalyst of the device is wave activated and is stimulated to form electron pairs which will cause the dissociation of nearby molecules (H2O, O2) to form positive and negative ions or free radicals (OH-, OH*…).With hydroxyl radicals (nascent oxygen) as the oxidant of the oxidation process, the oxidation and decomposition strength is even stronger than that of O2, O3, H2O2, CL2, for water treatment, stronger adsorption strength than activated carbon and have the disinfection ability that activated carbon don’t have.

The overall equipment, through the above materials and design principles, can make the water completely activated, and achieve above functions on water disinfection, elimination and prevention of biological slime, scale prevention and other water quality application purposes.

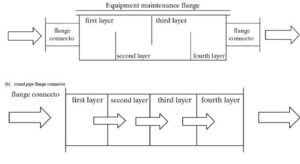

B. device appearance detailed drawing

Product specifications can be customized to match customer’s water usage, existing equipment and different piping conditions. The device have 2 types of

appearance:

(a) square flange connector

C. Device structure and materials

First layer: the device is made of low-density inert metal alloy foam as aggregate and special activated precision coating materials for the surface layer to minimize the damage caused by pipeline pressure transmission and to maximize activation of the contact area. Second layer: special hollow ceramic and static electric conduction net constitutes a layer of fluid electrostatic field, to eliminate & prevent biological slime growth habitat. Third layer: After the catalyst undergoes wave energy activation, the catalyst is stimulated to form electron pairs which will cause the dissociation of nearby

molecules (H2O, O2) to form positive and negative ions or free radicals (OH-, OH*…). With hydroxyl radicals (nascent oxygen) as the oxidant of the oxidation process, the oxidation and decomposition strength is even stronger than that of O2, O3,H2O2, Cl2, for water treatment, stronger absorption strength than activated carbon and have the disinfection ability that activated carbon don’t have.

The fourth layer: Using low density foam is an inert metal alloy aggregate device, activated materials surface precision special coating so that the pressure transmission pipeline to minimize the damage, and to increase the maximum activation of the contact area.

D. Device application

1. Industrial water quality activation and anti-scaling

2. Cooling towers wall scaling, bacterial growth, and biological slime prevention and elimination.

3. Comprehensive water quality improvement and activation process

4. Liquid fuel modification and activation

5. Reservoir and breeding farm water quality improvement

6. Improvement of livestock drinking water, change of agricultural water quality to high mineral activated water to avoid water damage.

7. hot water quality activation and suppression or prevention of limescale for smooth pipeline

E. Device Benefits

1. High economic efficiency, processing water volume is not limited.

2. Simple device, completely lightweight, compact body and simple installation.

3. Easy to maintain, does not consume electricity, no water blockage, online maintenance,completes immediately.

4. Since limescale problem depends on the minerals contained in water, changing the limescale form so that minerals precipitate in water rather than in heat exchange surface will completely solve the problem of scale.

5. Water is a natural solvent, if coupling polarity and the ability to dissolve water-soluble salts are enhanced, this device can improve mineral concentration ratio in order to remain in suspension.

6. Water treatment is most difficult for steam boilers and cooling towers. Chem-free device stop the minerals to float in suspension, making large particle precipitation.

7. Chem-free device is able to reduce the angle between the water molecules, increasing coupling polarity to prevent new scale and cause old scale to peel off.

8. Chem-free device scale-free operating system used in steam boilers and cooling towers, has long-term, stable effec.