Principle

Tar or coke is the residue of incomplete combustion of coal fired in the combustion chamber. The unburned carbon tar compounds, such as iron oxide, vanadium oxide, etc. stick to pipe wall surface and accumulate inorganic residue such as sulfide salt and vanadium salt. These corrosive sediments not only reduce heat transfer efficiency but also damage water pipes. DR. TIDE contains a catalyst, which when uniformly sprayed on coal before firing into the furnace combustion, can do rapid catalytic cracking of hydrocarbon bonds in the coal that makes selective hydrogenation of the double bond olefins creating Cis Olefinhydrocarbon to

complete the reaction process. The chemical reaction process is as follows:

CxHy + (2x + y)/2 O2 * (OH *) → x CO2 + y/2 H2O

The effectiveness of DR. TIDE is mainly due to its special hydrogenation ability, making the straight key chain olefin (by isomerization) into branched olefins. The active ingredients also provide sufficient oxygen to support combustion, making part of the hydrogen involved in combustion, to increase flame, heat value, and therefore improve efficiency.As a contribution to environmental protection, DR. TIDE also provides Nanoadsorption function. Elemental sulfur can be adsorbed on the cinder ash, reducing SOX dissipation into the air.

Boiler Maintenance and Benefit Analysis

(1). The DR. TIDE rapidly gasify inside the furnace, along with flue gas in the boiler system and uniformly does chemical reaction against tar. Flue gas passes through super heater, economizer and air pre-heater of furnace gas system of the boiler, without dead ends. DR. TIDE spray system with four sets of automatic control for heterogeneity of sulfur, vanadium and sodium, also reduces cold-end corrosion and blockage on furnace pipes, economizer, preheater and dust collector. It helps in extending the service life of the boiler, saving on cost of replacement parts, and let the boiler system run in the best condition.

(2). Prevent abnormal shutdown due to tar or coke corrosion problems,ensuring normal operation.

Environmental benefit analysis

This remover promotes complete fuel combustion to reduce unburnedmatters in flue gas such as the proportion of sulfur (SOX) content, to reduce air and environment contamination.

Features:

(A) Simple to use, special PLC automatic spraying control equipment.

(B) Equally effective for both sawdust burning or coal-fired boilers.

(C) Simultaneous application during normal operation, spraying evenly,complete reaction, reduces manpower.

(D) To new boilers or boilers after de-coking, the remover keeps fire side clean.

Dosage & Application:

Dilute 20 liters of DR. TIDE in 500 liters of water and use this mixture for every 50 metric tons of coal. The mixture will raise the moisture content of coal by 1%. After DR. TIDE is evenly sprayed on coal using an exclusive spraying machine, any grinding or further processing will not be affected. DR. TIDE allows an increase of 2~4% in the total amount of coal moisture content (total moisture content not to exceed 28%). When coal enters combustion chamber, there is rapid gasification, chemical reaction and full combustion with coal, thereby inhibits tar from forming and decomposes old tar, making the combustion chamber heat cycle run smoothly.

Comparison of Factors Affecting Tar Formation:

| Change Factors | More Tar | Less Tar |

| Coal Type Variation | Simultaneous mixed combustion of a variety of coals | Firing only a single type of coal |

| Coal Source | China coal contains impurities, has more problems and easy to cause tar. The higher ratio of China coal, the greater the chance of tar | Australia and Indonesia coal have less impurities, not easy to produce tar |

| Load variation | 24 Hrs whole year continuous load, tar has no chance to fall | Load changes frequently, tar falls automatically due to temperature changes |

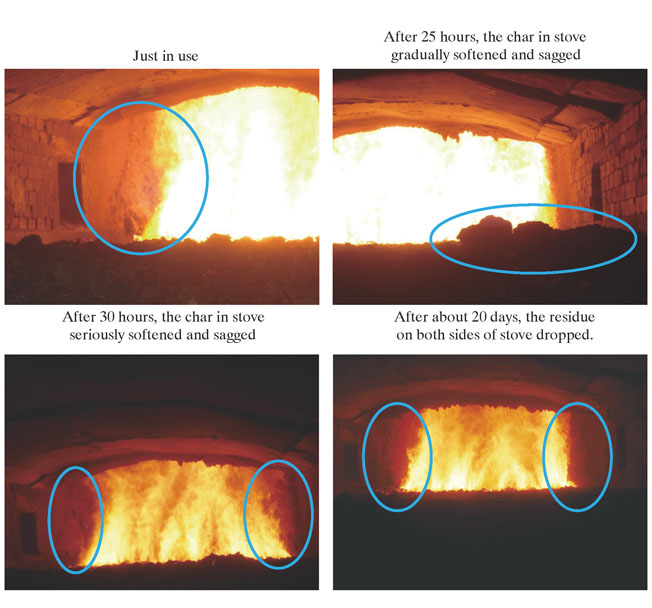

The effect of DR. TIDE on coal-fired boilers