Gas molecular clusters become smaller after being cut by lines ofmagnetic force, so oxygen accepting areas are increased.

Transformation of gas molecules from negatively charged to positively charged, makes molecular binding with negatively charged oxygen atom easier.

Product advantages

More than two decades of production and sales performance, device are used all over the world.

Cost effective, the payback period is less than 12 months.

Device work without human operation, with stable performance and remarkable efficiency.

No need of cleaning nozzle to get rid of carbon (coke) deposits, extending nozzle life.

Other than initial investment, there is no additional running costs.

Greatly reduces the carbon content in gas emission and protecting the environment,easy installation and without downtime during maintenance.

5 years quality warranty for core components.

Efficiency

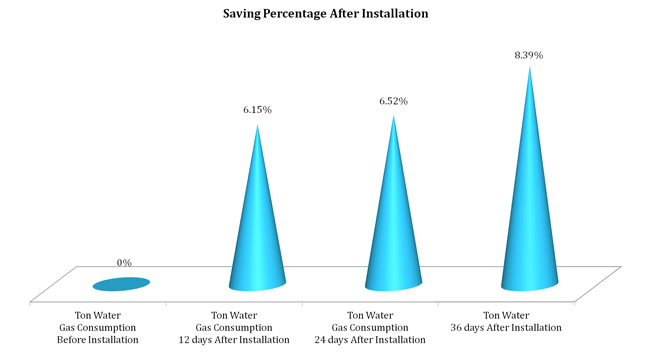

Gas savings of 2% or higher (the highest energy savings of domestic users is up to 17%)

Reduction of CO in gas emissions : 25% ~ 95%

Reduction of HC in gas emissions : 14% ~ 75%

Reduction of NOx in gas emissions : 5 ~ 50%

Significant reduction of carbon deposits on nozzle

Proven technology

OOO Corporation

OO factory

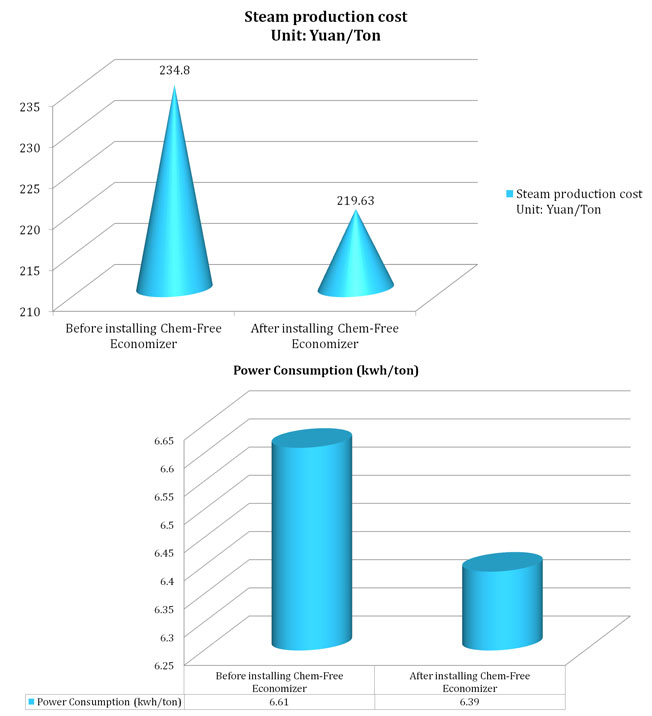

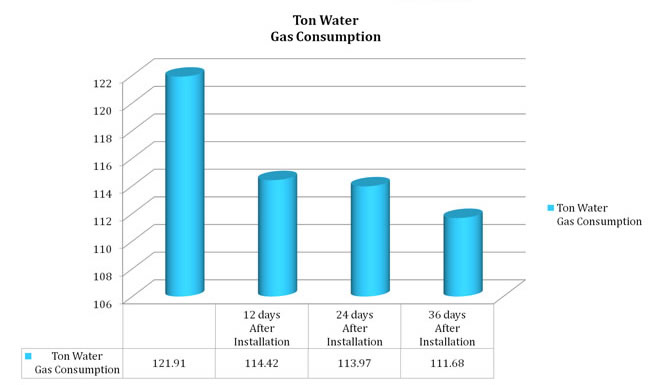

Comparative Data Before and After Installation:

Steam production ratio increased by 5.09% (including temperature rise of 4 degrees)

Power consumption per ton of steam decreased by 0.22 kwh

Cost of steam reduced by 15.17 yuan/ton

Since boiler feed water temperature increased from 80 degrees to 84 degrees , every metric ton of steam saves gas costs of 1.42 yuan.Deducting the rise in temperature, cost of steam reduced by 13.75